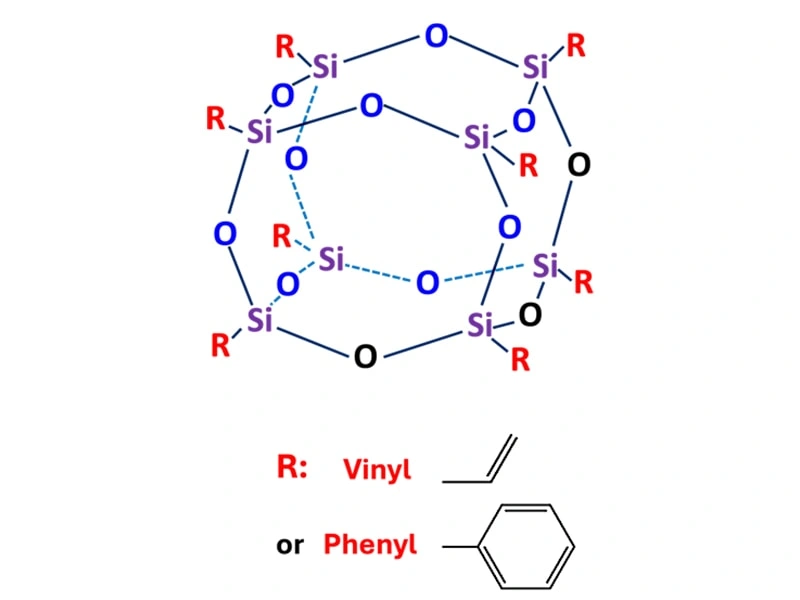

Octavinyl-phenyl POSS (VP-POSS) is an advanced organic-inorganic hybrid nanomaterial characterized by a silsesquioxane cage core, primarily (SiO1.5)8, with a balanced 1:1 ratio of vinyl and phenyl groups. This unique structure combines the reactivity of vinyl groups with the high refractive index and thermal stability of phenyl groups, making VP-POSS a versatile material for high-performance applications.

VP-POSS is a robust solution for applications requiring outstanding mechanical strength, thermal stability, and optical clarity, offering unmatched performance in demanding industrial and technological environments.

*This product is co-developed and jointly produced with Shenzhen Institute for Advanced Polymer Materials (SIAP).

Octavinyl-phenyl Polyhedral Oligomeric Silsesquioxane

N/A

| Property | Description |

| Chemical Name | Octavinyl-phenyl Polyhedral Oligomeric Silsesquioxane |

| CAS Number | N/A |

| Molecular Weight | 833 g/mol |

| Melting Point | > 350 oC |

| Refractive index | 1.50 ± 0.005 |

| Appearance | Clear and colorless liquid |

| Density | 1.18-1.23 g/cm³ |

| Solubility | Soluble in chloroform, toluene, THF; slightly soluble in ethanol; insoluble in water |

| Purity | ≥ 98.0% |

Octavinyl-phenyl POSS is highly versatile due to the reactive vinyl groups, enabling it to participate in various chemical reactions with organic polymers. Key features include superior reinforcing properties, effective hardening, and excellent compatibility, making it ideal for polymer modification, nanocomposites, and functional coatings.

The vinyl groups enable hydrosilylation and thermosetting properties, providing exceptional heat resistance, adhesion, water repellency, and aging resistance. Meanwhile, the phenyl groups contribute a high refractive index, enhancing its use as a reinforcing filler in high-refractive-index silicone rubbers, optical-grade encapsulation silicones (e.g., for electronics, LEDs, and solar panels), and highly transparent, high-hardness silicone rubbers.

Polymer Modification: Improves thermal stability, mechanical strength, and chemical resistance in polymers such as silicone rubbers, epoxies, and acrylics via radical polymerization or addition reactions.

Nanocomposites: Acts as a crosslinking agent and filler for high-performance coatings, adhesives, and composites, improving hardness, wear resistance, and thermal stability.

Functional Coatings: Used in hydrophobic, corrosion-resistant, and heat-resistant coatings for industries such as aerospace and automotive.

High-Temperature Materials: Used in aerospace and automotive industries for heat-resistant components.

Note: This document does not contain the product safety information necessary for safe use. Prior to handling, please review the product and material safety data sheets along with hazard information. To obtain material safety data information, reach out to SIAP.

Keep away from fire and direct sunlight.

Store in a cool, dry, and well-ventilated area, away from direct sunlight and high temperatures.

It has 12 months shelf life in closed containers.

Recommended storage temperature: 0°C - 25°C.

Avoid contact with strong oxidizers or acidic substances.

Products beyond the shelf life can be usable, if quality check passed.

Standard Packaging: 100 g/ bottle, 500 g/ bottle, 1 kg/ bottle, 25 kg/ bottle.

Packaged in light-proof sealed containers; custom packaging available upon request.

* Required fields