Silane Crosslinking Agents in Glass Fiber Composites

Enhancing Strength and Durability

Glass fiber-reinforced polymers (GFRPs) are vital in aerospace, automotive, and wind energy sectors. However, the brittleness of glass fibers and weak interfacial bonding with polymer matrices can limit their performance.

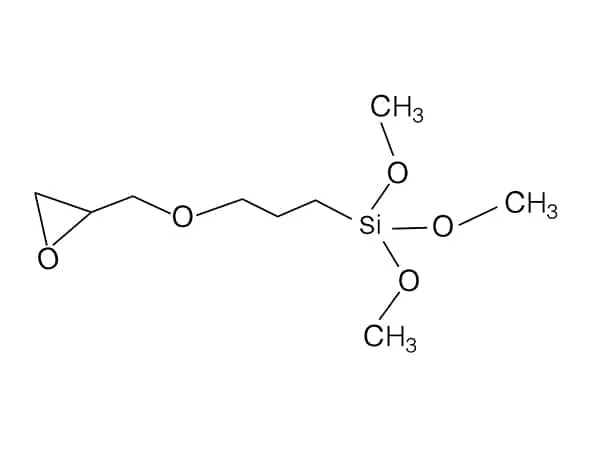

Silane crosslinking agents, such as vinyltrimethoxysilane (VTMS), introduce covalent bonds between glass fibers and resins like polyester or epoxy. During processing, the silane’s methoxy groups hydrolyze, bonding to the glass surface, while its reactive vinyl groups crosslink with the polymer. This dual action strengthens the fiber-matrix interface, improving impact resistance and fatigue life by up to 25%.

For example, crosslinked GFRP helicopter blades demonstrate 30% higher vibration resistance, extending service intervals. By optimizing silane chemistry, manufacturers achieve lightweight, high-performance composites for demanding environments.