The function of a coupling agent is to act as a molecular bridge between two dissimilar materials, typically an organic matrix (e.g., polymers, resins) and an inorganic filler or substrate (e.g., glass fibers, minerals, metals). This enhances interfacial bonding and overall composite performance. Below is a structured breakdown of its key functions:

1. Primary Function: Interfacial Adhesion

Bridging Mechanism:

Coupling agents chemically bond to both materials:

Inorganic Side: Reactive groups (e.g., silanol -Si-OH, titanate) form covalent bonds with hydroxylated surfaces (e.g., glass, metals).

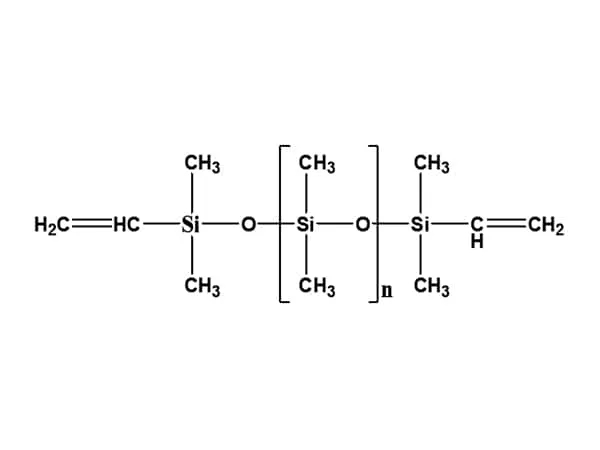

Organic Side: Functional groups (e.g., methacrylate, amino, epoxy) react with the polymer matrix (e.g., copolymerization, hydrogen bonding).

Example:

Silane coupling agents (e.g., γ-MPS) bond silica fillers to methacrylate resins in dental composites.

2. Enhanced Mechanical Properties

Stress Transfer: Strong interfacial bonding ensures efficient load transfer, improving:

Tensile/flexural strength

Fracture toughness

Wear resistance

Reduced Debonding: Prevents filler-matrix separation under stress, minimizing crack propagation.

3. Environmental Resistance

Hydrolytic Stability: Forms moisture-resistant bonds (e.g., Si-O-Si in silanes), critical for applications in wet environments (e.g., dental composites, marine coatings).

Chemical Resistance: Protects against degradation from acids, solvents, or UV exposure.

4. Improved Filler Dispersion

Surface Modification: Makes fillers (e.g., glass fibers, nanoparticles) more compatible with the matrix, ensuring uniform distribution.

Reduced Agglomeration: Prevents filler clumping, enhancing optical, electrical, or mechanical properties.