Silane coupling agents are indispensable in modern adhesive formulations, bridging organic polymers and inorganic substrates to create durable, high-performance bonds. Their unique dual reactivity—combining hydrolyzable alkoxy groups and organofunctional terminals—enables covalent bonding across interfaces, making them ideal for challenging industrial applications.

Key Applications

Structural Adhesives for Metals and Composites

Mechanism: Silanes (e.g., 3-aminopropyltriethoxysilane) form chemical bonds with metal oxides (aluminum, steel) and polymer matrices (epoxy, polyurethane).

Performance: Increases shear strength by 30–50% (ASTM D1002) and enhances resistance to thermal cycling (-40°C to +150°C).

Use Case: Automotive assembly adhesives for bonding aluminum body panels.

Flexible Sealants for Glass and Ceramics

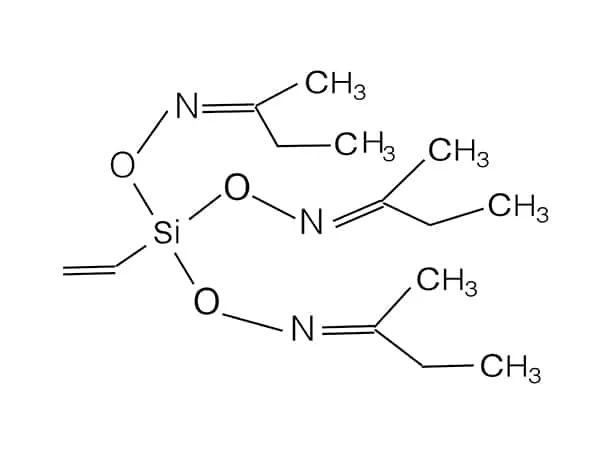

Function: Vinyltrimethoxysilane improves adhesion to glass surfaces while maintaining flexibility.

Advantage: Reduces delamination in silicone sealants exposed to UV and humidity (ISO 11600).

Electronics Adhesives

Role: Epoxy-functional silanes enhance adhesion to printed circuit boards (PCBs) and prevent ionic contamination.

Why Choose Our Silane Coupling Agents?

Tailored Reactivity: Customizable organofunctional groups (amine, epoxy, vinyl) for specific substrates.

Low Volatile Organic Compounds (VOCs): Eco-friendly formulations comply with REACH and EPA standards.

Industry Example

A leading aerospace manufacturer achieved a 40% improvement in composite-to-metal bond durability using our amino-silane adhesive additives, passing FAA flammability tests (FAR 25.853).

Conclusion

Silane coupling agents redefine adhesive performance, offering unmatched durability and versatility. Contact us to optimize your adhesive formulations for extreme environments.