Technical Mechanism

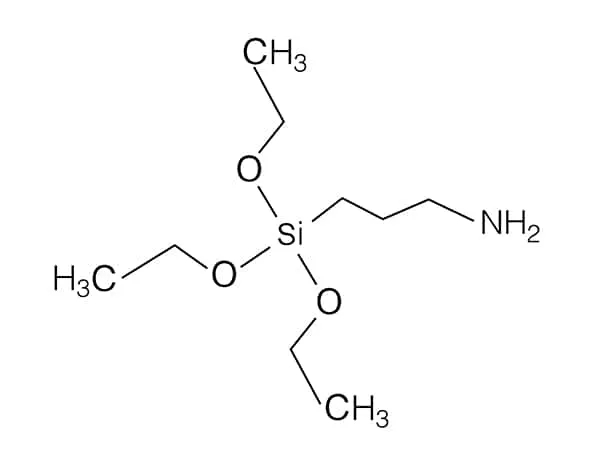

Non-ferrous metals like aluminum and zinc alloys present unique adhesion challenges due to their oxide layers. Mercapto silanes (e.g., 3-mercaptopropyltrimethoxysilane) utilize thiol (-SH) groups that form strong coordination bonds with metal surfaces. This interaction converts unstable hydroxyl groups into stable metal-sulfur complexes, achieving interfacial energy matching.

Performance Validation

Peel Strength:

Untreated aluminum: 2.1 N/mm

Silane-treated: 5.8 N/mm

Humidity Resistance (85°C/85% RH):

1,000 hours without blistering

Chemical Compatibility:

Coating Type Adhesion Improvement

Epoxy Powder 220%

PVDF Fluoropolymer 180%

Industrial Case

Boeing's 787 Dreamliner employs mercapto silane pretreatments for aluminum fuselage coatings, reducing paint delamination incidents by 73% in tropical operating conditions.